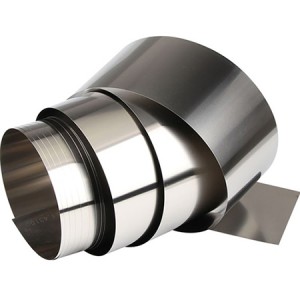

Alloy 46 UNS K94600 bar / sheet/ strip

Common Trade Names: Alloy 46, 4J46, Fe-46Ni, UNS K94600, NiLo46

Alloy 46 is obtained at a given termperature range by adjusting the content of nickel internal energy and the expansion coefficient of different softglass and ceramic matching a series of expansion alloy, its expansion coefficient and the Curie temperature increases with the increase of nickel content.The assembly is widely used in electric vacuum industry the sealing structure ofthe material.

Alloy 46 Chemical Composition

|

Ni |

Fe |

C |

Cr |

P |

Si |

Co |

Mn |

Al |

S |

| 45.0~47.0 | Bal | ≤0.05 | ≤0.025 | ≤0.02 | ≤0.3 | - | ≤0.80 | ≤0.10 | ≤0.02 |

Alloy 46 Basic physical Constants and Mechanical Properties

|

Brand |

Thermal conductivity |

Specific heat capacity |

Density |

Melting point(℃) |

Electric resistivity |

Curie point |

|

Alloy 46 |

14.7 |

502J |

8.18 |

1427 |

0.49 |

420 |

Alloy 46 coefficient of linear expansion

|

Grade |

Heat treatment of samples |

Average coefficient of linear expansion |

||

|

20~300°C |

20~400°C |

20~500°C |

||

|

Alloy 46 |

Heat to 850~900°C in a protective atmosphere or in vacuum condition, hold for 1 hour, and then cool to 300℃ at a rate less than 300℃/h |

5.5~6.5 |

5.6~6.6 |

7.0~8.0 |

Notes:

1. The Vickers hardness of the annealed strip (sheet) should be no more than 170.

2. For the unannealed strip (sheet) delivered, after heat treat at 900℃, and then hold for 30 min, the Vickers hardness should be no more than 170.

Alloy 46 coefficient of linear expansion

|

Grade |

Average coefficient of linear expansion in different temperature, ā/(10-6/K) |

|||||

|

Alloy 46 |

20~100℃ |

20~200℃ |

20~300℃ |

20~400℃ |

20~500℃ |

20~600℃ |

|

6.8 |

6.5 |

6.4 |

6.4 |

7.9 |

9.3 |

|

Alloy 46 Mechanical Property

|

Grade |

Heat treatment temperature,℃ |

Tensile strength, sb/MPa |

Tensile stretch, δ(%) |

Vickers hardness |

Grain size |

| Alloy 46 |

750 |

527.5 |

34.8 |

137.4 |

7 |

|

850 |

510 |

35.4 |

134.6 |

6 |

|

|

950 |

483.5 |

36.7 |

128.1 |

6~5 |

|

|

1050 |

466.5 |

34.3 |

125.6 |

5~4 |

Alloy 46 Magnetic Property

|

Grade |

magnetic induction |

remanent magnetic induction/ Br/T |

coercivity |

maxmum perameability |

|

|

Alloy 46 |

B10/T |

Bl00/T |

|

|

|

|

1.58 |

1.6l |

0.31 |

2.96 |

55.5 |

|

Alloy 46 Application field:

Alloy 46 is used mainly for precision impedance diaphragm, with synthetic sapphire, soft glass, ceramic sealing