News

-

Kovar -29HK Material Application

Resently, We get order from India and Korea Client, they have purchased us Kovar bars and Kovar sheets, They use kovar bar to make pins ,kovar sheet to make cover plate. below are the finished products,they produced. 4J29(KOVAR) alloy has a linear expansion coefficient similar to borosilicate ha...Read more -

Inconel rods transform industry with unparalleled performance and durability

Inconel rod is an important part of the nickel-based alloy family and has become a game-changer across industries, revolutionizing the way manufacturers approach critical applications. Inconel rod is renowned for its exceptional performance in extreme environments, raisi...Read more -

Revolutionary Developments in Nickel-Based Alloys and Rods

Recent breakthroughs in the metallurgical world have seen the emergence of highly advanced nickel-based alloys and rods, revolutionizing various industries. Leading this wave of innovation are Aloys Par and Rod, two leading entities that have made significant advances in...Read more -

The Growing Importance of Cobalt-Based Alloys in Manufacturing – See Sekonic Metals Technology Co., Ltd

Cobalt-based alloys have seen a significant increase in usage in manufacturing owing to their unique properties, making them suitable for various applications in different industries. Cobalt-based alloys are known for their high-temperature strength, wear and corrosion r...Read more -

ErNiFeCr-2 Welding Wire: Best Choice for High Performance Applications

ErNiFeCr-2 (Inconel 718 UNS NO7718) welding wire is a popular choice for a variety of high-performance applications because it has a unique combination of properties that make it strong, corrosion-resistant, and capable of withstanding high temperatures. ErNiFeCr-2 weldi...Read more -

Precautions for Monel alloy welding

1.Material selection and manufacturing welding are in accordance with the ASME Boiler and Pressure Vessel Code and ANSI Pressure Pipeline Code . 2. The chemical composition of the metal of the welded parts and welded materials must comply with the provisions of the stan...Read more -

Sekoinc Metals conducts safety fire drill

On December 20 and 21, 2022, Sekoinc Metals organized all employees of the plant to carry out a fire safety drill. This drill is an important work of our company’s emergency management in 2022. Judging from the results of the drill, the drill was well-guided, well-prepared, well-organized,...Read more -

{Product introduction}N08020

N08020 corresponding brand: alloy20, baiUNS N08020, NS143, Inconel alloy20/NAS 335X, W.NS.2.4660, Nicrofer 3620 NP-Alloy20,ATI 20, NiCr20CuMo(De)OCr20Ni35Mo3Cu4Nb N08020 Heat treatment :900-1150℃ for 1-2 hours, rapid air cooling or water cooling. N08020 corrosion resistance and main use environme...Read more -

What is the difference between MonelK500 and Monel K400?

MONEL Alloy K-500 (UNS N05500/ W.R.2.4375) is a nickel-copper alloy that combines the advantages of excellent corrosion resistance with greater strength and hardness of MONEL alloy 400. Aluminum and titanium were added to the nickel-copper base and heated under controlled conditions to precipitat...Read more -

Sekonic Metals Group on Epidemic Prevention and Control

Recently, as the epidemic situation has become increasingly severe,Sekonic Metals has always given top priority to the health and safety of its employees, striving to do a good job in its own epidemic prevention and recovery, and actively organizing volunteers to hel...Read more -

Do you know how to choose parts and materials?

Selecting the material to be used from a variety of materials is a work restricted by many factors.Therefore, how to choose the material of parts is an important part of parts design.The principle of selecting mechanical parts materials is: the required materials should ...Read more -

Staff presence

Sekonic Metals organizes a walking challenge for employees October 19th, in order to enrich employees' cultural life, strengthen team building, create a target-locked, positive and enterprising atmosphere.Organized by the culture Department of the enterprise, the staff w...Read more -

[Summary] Heat treatment 30 questions and answers

Asked 30 directories what are the cormmonly used quenching methods and explain the principle of selecting different quenching methods? Quenching method: 1. Single liquid quenching -- cooling process in a quenching med...Read more -

What is stainless steel?

Stainless steel material: Stainless steel material is a kind of material, has close to the mirror brightness, touch hard and cold, belongs to the more avant-garde decoration material, has excellent corrosion resistance, molding, compatibility and toughness and other se...Read more -

High temperature spring production, introduction, types and commonly used materials

High temperature spring refers to the use of special materials, working in high temperature environment can have good elasticity of the spring. Production of high temperature spring: All kinds of high and low temperature resistant -200~+950 spring using special materials...Read more -

Exquisite Al-Si alloy metallographic pictures

Deformed grain structure of 99.999% Al; Barker's Reagent, Polarized Light Al-1% Si as-cast specimen with Si particles in an α-Al matrix; "Si Blue" etch Al-7.12% Si, as-cast, with primary α-Al dendrites and an a-Al/Si eutectic; "Si Blue" etch Al -11....Read more -

Methods for solving inclusion defects

*Defect judgment: There are obvious spot, block and strip defects on the surface of the steel plate. After annealing, it will appear obvious white or black. In serious cases, surface peeling, irregular defects and uneven concave-convex defects will appear. It is easy to ...Read more -

Stop Corrosion Before It Starts!

Corrosion can occur when an alloy is exposed to moisture and other elements or chemicals which cause the material to deteriorate. Sekonic Metals has put together a list of tips to help you avoid corrosion. Choose Stainless Steel: Although all metals can corrode, stainless steels are m...Read more -

Heat Treatment For Nickel Alloys

Nickel Alloys Heat Treatment process generally includes three processes of heating, heat preservation, and cooling, and sometimes there are only two processes of heating and cooling. These processes are connected and uninterrupted. Heating Heating is one of the im...Read more -

Normal Nickel Alloys Density

Material Name Density(g/m3) Invar 36(4J36) 8.1 GH2132/660A 7.99 GH131 8.33 GH136 8.03 GH696 7.93 GH3030/XH78T 8.4 GH3128 8.81 GH3044 8.89 GH3039 8.3 GH4049 8.44 Hastelloy X (GH536 ) 8.28 Inconel 625(GH625) 8.44 ...Read more -

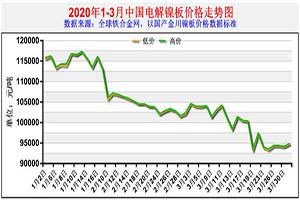

Nickel Industry

Excerpt from the SMM Nickel Industry Chain Weekly Report: Recently the US election event affecting market fundamentals, because of the influence of the stainless steel metal futures price falls, nickel pig iron’s price is difficult to achieve, and present the weaker risk, weak industrial ch...Read more -

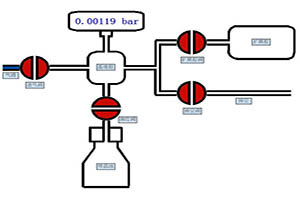

Production Process

Sekonic Metals Group have a series of production equipments imported from American and Germany,Such us 2-tonsVacuum Induction Furnace,5-tons electroslag refining furnace, environmental advanced bright annealed furnace and gas protection annealing furnace, precsision cold rolling machine,broaching...Read more -

New Website Online

Celebrate Sekonic Metal Group New Website online Thanks to the efforts of all of our employee and our partner factories,and apprecited with our old and new clients continue support and trusting , the company's annual export sales perfromance this year Holding USD12,000,...Read more