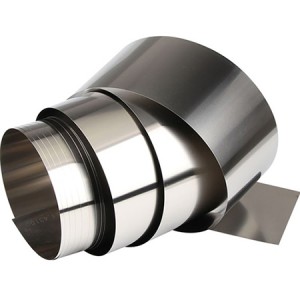

Stainless Steel Nitronic 60 bar/ Pipe/Ring /Sheet

Common Trade Names: Nitronic 60, Alloy 218,UNS S21800

Nitronic 60 is known for its excellent galling resistance, even at elevated temperatures. The additions of 4% silicon and 8% manganese inhibit wear, galling, and fretting. It is commonly used for various fasteners and pins that require strength and resistance to galling. It maintains decent strength up to temperatures of 1800°F and has oxidation resistance similar to that of 309 stainless steel. The general corrosion resistance is between that of 304 and 316 stainless steel.

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

N |

P |

S |

|

Nitronic 60 |

Min. |

8 |

16 |

59 |

|

7 |

3.5 |

0.08 |

|

|

|

Max. |

9 |

18 |

66 |

0.1 |

9 |

4.5 |

0.18 |

0.04 |

0.03 |

|

Density

|

8.0 g/cm³

|

|

Melting point

|

1375 ℃

|

|

Alloy status |

Tensile strength Rm N/mm² |

Yield strength RP0.2 N/mm² |

Elongation A5 % |

Brinell hardness HB |

| Solution treatment |

600 |

320 |

35 |

≤100 |

Nitronic 60 Standards and Specifications

AMS 5848,ASME SA 193, ASTM A 193

Nitronic 60 Available Products in Sekonic Metals

Why Nitronic 60 ?

• Nitronic 60 Stainless Steel provides a significantly lower cost way to fight galling and wear compared with cobalt-bearing and high nickel alloys. Its uniform corrosion resistance is better than type 304 in most media. In Nitronic 60 ,chloride pitting is superior to Type 316

• Yield strength at room temperature is nearly twice that of 304 and 316

• Nitronic 60 provides excellent high temperature oxidation resistance and low-temperature impact resistance

Nitronic 60 Application field:

Used extensively in the Power, Chemical, Petrochemical, Food and Oil & Gas industries with an array of uses including expansion joint wear plates, pump wear rings, bushings, process valve stems, seals and logging equipment.