Factory Free sample Alloy 20 Round Bar - Haynes 25 (Alloy L605-Co350) seal ring – Sekonic

Factory Free sample Alloy 20 Round Bar - Haynes 25 (Alloy L605-Co350) seal ring – Sekonic Detail:

Haynes 25 (Alloy L625, Co350) Foring ring, Seal Ring

♦ Size: According to clients requirements

♦ Condition: Forged, polished Surface

♦ Application for : Steam turbine, Engine parts, Vales Seat ring

♦ Sample order can be accept

♦ Delievery Date :15-25days

Haynes® 25 (L-605) is a cobalt based alloy that combines good forming and excellent high temperature properties. The alloy is resistant to oxidation and carburization to 1900 °F. Alloy 25 can only be hardened significantly by cold working. Cold working will increase creep strength up to 1800 °F and stress rupture strength uo to 1500 °F. Strain aging at 700 – 1100 °F improve creep and stress rupture strengths below 1300 °F.

Haynes 25 Chemical Composition

| Alloy |

% |

Ni |

Cr |

Co |

Mn |

Fe |

C |

Si |

S |

P |

W |

|

Haynes 25 |

Min. |

9.0 |

19.0 |

balance |

1.0 | - | 0.05 | - | - | - |

14.0 |

|

Max. |

11.0 |

21.0 | 2.0 | 3.0 | 0.15 | 0.4 | 0.03 | 0.04 | 16.0 |

Haynes 25 Physical Properties

| Density | 9.13 g/cm³ |

| Melting point | 1330-1410 ℃ |

Haynes 25 Mechanical Properties

| Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution treatment | 960 | 340 | 35 | ≤282 |

Haynes 25 Available Products in Sekonic Metals

Haynes 25 bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Haynes 25 welding wire

Supply in welding wire and spring wire in coil form and cut length.

Haynes 25 Forging Ring

Forging Ring or gasket,size can be customized with bright surface and precision tolerance

Haynes 25 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Haynes 25 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

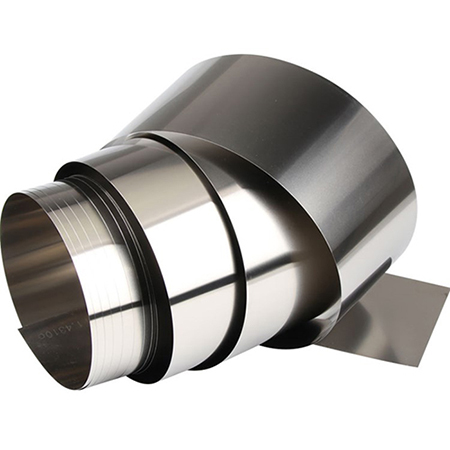

Haynes 25 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Haynes 25 Fasteners

Haynes 25 materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Why Haynes 25 ?

1. Medium endurance and creep strength below 815.

2. Excellent oxidation resistance below 1090℃.

3. Satisfactory forming, welding and other technological properties.

Haynes 25 Application field:

Haynes 25 has given good service in many jet engine parts. Some of these include turbine blades, combustion chambers, afterburner parts, and turbine rings. The alloy has also been used successfully in a variety of industrial furnace applications including furnace muffles and liners in critical spots in high temperature kilns.

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Nickel Based Alloys ?

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Factory Free sample Alloy 20 Round Bar - Haynes 25 (Alloy L605-Co350) seal ring – Sekonic , The product will supply to all over the world, such as: Hungary, Karachi, Anguilla, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.