High reputation Inconel Alloy 625 - Stellite 6/ Stellite 6B/ Stellite 12 valves seat Ring/ Sleeve – Sekonic

High reputation Inconel Alloy 625 - Stellite 6/ Stellite 6B/ Stellite 12 valves seat Ring/ Sleeve – Sekonic Detail:

Stellite 6/6B Valves Seat Ring/ Sleeve

♦ Material: Stellite Alloys, Stellite 6, Stellite 6B, Stellite 12

♦ Forms: Ring, Sleeve as per clients drawing or specification

♦ Surface: Polished/ Grinding

♦ Tolerance:+/-0.01 mm On OD and ID

♦ Hardness: 38-55 HRC

♦ Standards :AMS 5387 ect

Stellite 6 or cobalt 6 cobalt based alloys produced by centrifugal casting or sand moulding, used in bushings and wear rings to improve wear resistance.

Condition: Casting, stress relief before processing

Heat treatment: stress relief: heat the casting to the minimum 800℃, hold for 1-4 hours slow cooling.

Process: All castings of the same batch shall be of the same quality without pores, pores, hard spots, shrinkage defects, cracks or other harmful defects.Single castings with isolation holes below 0.5 mm are not allowed to be repaired, plugged or welded.

Semi-finished castings for EMS final machining shall be provided in “Machining Inspection Status” to allow casting to be inspected prior to shipment.

Stellite Alloys Chemical compositions and properties (%)

| Material | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density(g/cm3) | Hardness(HRC) |

| Stellite 3 | 2.0-2.7 | 1.0 | 1.0 | 29-33 | 3.0 | 11-14 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.55 | 51-55 | |

| Stellite 6 | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.35 | 38-44 |

| Stellite 12 | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 |

Application:

Stellite6B alloy is one of the cobalt-based wear resistant Bai alloys, wear resistance and toughness, can adapt to most conditions, a wide range of applications, hardness in 37-45HRC;It is mainly used for chemical wear-resisting plate, wear-resisting rod, steam chemical valve seat, steam turbine blade protection, anti-erosion bushing, hot dip galvanized submerged roller and other parts;Compared with WR6 (Stellite6) WR6B, WR6B has better high temperature wear resistance

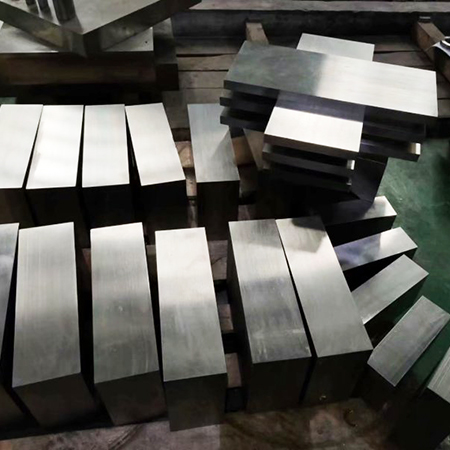

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Cobalt based Alloys

Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of High reputation Inconel Alloy 625 - Stellite 6/ Stellite 6B/ Stellite 12 valves seat Ring/ Sleeve – Sekonic , The product will supply to all over the world, such as: Paris, Birmingham, Hamburg, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.