Manufacturer for Alloy 601 - Haynes Alloy 188 Udimet 188 Round bar Supplier – Sekonic

Manufacturer for Alloy 601 - Haynes Alloy 188 Udimet 188 Round bar Supplier – Sekonic Detail:

Common Trade Names:Haynes 188, Alloy 188, GH5188, UNS R30188

Hayness 188 (Alloy 188)is a cobalt-base alloy with excellent high -temperature strength and good oxidation resistance to 2000°F (1093°C). The high chromium level coupled with small additions of lanthanum produce an extremely tenacious and protective scale. The alloy also has good sulfidation resistance and excellent metallurgical stability as displayed by its good ductility after prolonged exposure to elevated temperatures. Good fabricability and weldability combine to make the alloy useful in gas turbine applications such as combustors, flame holders,liners and transition ducts.

Alloy 188 Chemical Composition

| C | Cr | Ni | Fe | W | La | Co | B | Mn | Si |

| 0.05 0.15 | 20.0 24.0 | 20.0 24.0 | ≦ 3.0 | 13.0 16.0 | 0.02 0.12 | bal | ≦ 0.015 | ≦ 1.25 | 0.2 0.5 |

Alloy 188 Physical properties

| Density (g/cm3) |

Melting point (℃) |

Specific heat capacity (J/kg·℃) |

Thermal expansion coefficient ((21-93℃)/℃ ) |

Electric resistivity (Ω·cm) |

| 9.14 | 1300-1330 | 405 | 11.9×10E-6 | 102×10E-6 |

Alloy 188 Mechanical Properties

Instantaneous(bar,typical hot treatment)

| Test temperature ℃ |

Tensile strength MPa |

Yield strength (0.2yield point)MPa |

Elongation % |

| 20 | 963 | 446 | 55 |

Alloy 188 Standards and Specifications

AMS 5608, AMS 5772,

| Bar/Rod | Wire | Strip/Coil | Sheet/Plate |

| AMS 5608 | AMS 5772 | ||

Alloy 188 Available Products in Sekonic Metals

Alloy 188 Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Alloy 188 welding wire

Supply in welding wire and spring wire in coil form and cut length.

Alloy 188 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Alloy 188 seamless tube

Standards size and customized dimension can be produced by us with small tolerance

Alloy 188 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Why Haynes 188 ?

• Strength and oxidation resistant to 2000°F

• Good post-aging ductility

• Resistant to sulfate deposit hot corrosion

Haynes 188 Application field:

Gas turbine engine combustor cans, spray bars, flame-holders and afterburner liner

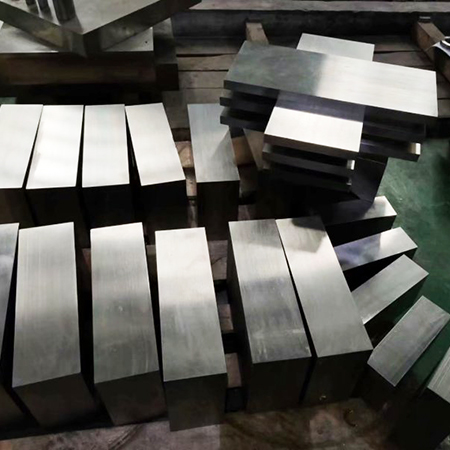

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Cobalt based Alloys

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Manufacturer for Alloy 601 - Haynes Alloy 188 Udimet 188 Round bar Supplier – Sekonic , The product will supply to all over the world, such as: Dubai, Ottawa, Kuala Lumpur, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.