Manufacturer for Alloy C-276 Flanges - Titanium Strip and Foil – Sekonic

Manufacturer for Alloy C-276 Flanges - Titanium Strip and Foil – Sekonic Detail:

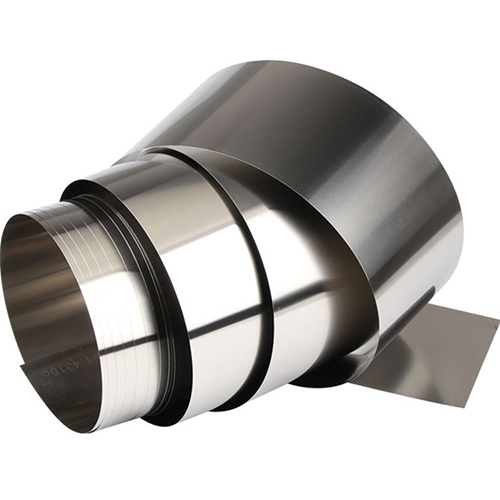

• Tittanium Strip and Foil Materials: Pure Titanium(CP) and Titanium alloy foil,Grade1, Grade 2, Grade 5, Grade 5, Grade 7 and Grade 9

• Forms: Single strip, in coil, or on spool. Slitting service available

• Dimension: Thickness: ≥0.01mm : 20~1000mm, Length: As the Request

• Conditions: Cold rolled(Y)~Hot rolled(R)~Annealed (M)~Solid Status

• Standards: ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 etc

• Appilications:Electronics, chemicals, watches, glasses, jewelry, sporting goods, machinery, plating equipment, environmental equipment, golf and precision machining industries.

| Titanium Alloys Material Common Name | ||

|

Gr1 |

UNS R50250 |

CP-Ti |

|

Gr2 |

UNS R50400 |

CP-Ti |

|

Gr4 |

UNS R50700 |

CP-Ti |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

|

G9 |

UNS R56320 |

Ti-3AL-2.5V |

|

G11 |

UNS R52250 |

Ti-0.15Pd |

|

G12 |

UNS R53400 | Ti-0.3Mo-0.8Ni |

|

G16 |

UNS R52402 | Ti-0.05Pd |

|

G23 |

UNS R56407 |

Ti-6Al-4V ELI |

Titanium Strip and Foil : We mainly provide pure titanium Strip of Gr1, Gr2, Gr4 grades; For titanium alloy Foil, We mainly provide Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 and other grades,They are produced on the basis of titanium plate with further cold rolling; the production process of titanium sheet is more complicated. The deformation control is more strictly in the process of rolling.That can be cut in different sizes according to the customer’s needs, greatly shorten the time of delivery.

♦ Titanium Strip Chemical composition ♦

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C (≤) |

O (≤) |

N (≤) |

H (≤) |

Fe (≤) |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5 6.75 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12 0.25 |

— |

0.12 0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5 3.5 |

2.0 3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12 0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6 0.9 |

0.2 0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04 0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5 6.5 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

♦ Titanum Alloy Strip Physical properties♦

|

Grade |

Physical properties |

|||||||

|

Tensile strength Min |

Yield strength Min (0.2%,offset) |

Elongation in 4D Min (%) |

Reduction of Area Min (%) |

Bend Test(Radius of Mandrel) |

||||

|

ksi |

MPa |

ksi |

MPa |

<1.8mm In thicknes |

1.8-4.8mm In thickness | |||

|

Gr1 |

35 |

240 |

20 |

138 |

24 |

30 |

1.5T | 2.0T |

|

Gr2 |

50 |

345 |

40 |

275 |

20 |

30 |

2.0T | 2.5T |

|

Gr4 |

80 |

550 |

70 |

483 |

15 |

25 |

2.5T | 3.0T |

|

Gr5 |

130 |

895 |

120 |

828 |

10 |

25 |

4.5T | 5.0T |

|

Gr7 |

50 |

345 |

40 |

275 |

20 |

30 |

2.0T | 2.5T |

|

Gr9 |

90 |

620 |

70 |

483 |

15 |

25 |

2.5T | 3.0T |

|

Gr11 |

35 |

240 |

20 |

138 |

24 |

30 |

1.5T | 2.0T |

|

Gr12 |

70 |

483 |

50 |

345 |

18 |

25 |

2.0T | 2.5T |

|

Gr16 |

50 |

345 |

40 |

275 |

20 |

30 |

2.0T | 2.5T |

|

Gr23 |

120 |

828 |

110 |

759 |

10 |

15 |

4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

• Grade 1: Pure Titanium, relatively low strength and high ductility.

• Grade 2: The pure titanium most used. The best combination of strength

• Grade 3: High strength Titanium, used for Matrix-plates in shell and tube heat exchangers

• Grade 5: The most manufactured titanium alloy. Exceedingly high strength. high heat resistance.

• Grade 7: Superior corrosion resistance in reducing and oxidizing environments.

• Grade 9: Very high strength and corrosion resistance.

• Grade 12: Better heat resistance than pure Titanium. Applications as for Grade 7 and Grade 11.

• Grade 23: Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for surgical implant application.

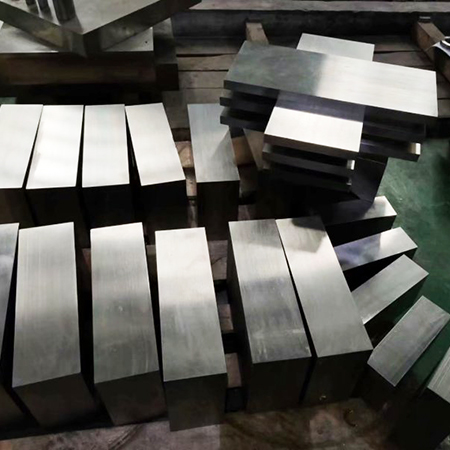

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Cobalt based Alloys

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Manufacturer for Alloy C-276 Flanges - Titanium Strip and Foil – Sekonic , The product will supply to all over the world, such as: Detroit, San Diego, Malaysia, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!