OEM/ODM China Nickel Alloy Flanges - Inconel 718 Tubing hanger – Sekonic

OEM/ODM China Nickel Alloy Flanges - Inconel 718 Tubing hanger – Sekonic Detail:

Inconel 718 Tubing Hanger/Oil Tubing hanger

♦ Material: Inconel 718

♦ A per clients drawing

♦ Application :oil and gas well completion system and a method of installing same

♦ We produce and Supply oil tube hanger according to clients drawing, our mateiral main are Inconel 718,Inconel 725,Monel 400 and Inconel x750, They Made of foriging bar with heattreatment condition, Dimension and tolearnace as per clients drawing.

Inconel® 718 is a precipitation-hardening nickel-chromium alloy with a high strength and good ductility up to 1300°F (704°C). this Alloy containing significant amounts of iron, columbium, and molybdenum, along with lesser amounts of aluminum and titanium.Nickel 718 also has relatively good weldability, formability, and excellent cryogenic properties compared to other precipitation hardening nickel alloys. The sluggish precipitation hardening response of this alloy allows it to be readily welded without hardening or cracking. Alloy 718 is non-magnetic. It maintains good corrosion resistance and oxidation resistance and is used for parts requiring high resistance to creep and stress rupture up to 1300°F (704°C) and oxidation resistance up to 1800°F (982°C).

Inconel 718 Chemical Composition

| Alloy |

% |

Ni |

Cr |

Fe |

Mo |

Nb |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

718 |

Min. |

50 |

17 |

balance |

2.8 |

4.75 |

0.2 |

0.7 |

||||||

|

Max. |

55 |

21 |

3.3 |

5.5 |

1 |

0.08 |

0.35 |

0.35 |

0.01 |

0.3 |

0.8 |

1.15 |

Inconel 718 Physical Properties

| Density | 8.24 g/cm³ |

| Melting point |

1260-1320 ℃

|

Inconel 718 Alloy minimum mechanical properties in the roomtemperature

| Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution treatment | 965 | 550 | 30 | ≤363 |

Inconel 718 Available Products in Sekonic Metals

Inconel 718 Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fasteners and other spare parts

Inconel 718 welding wire & Spring wire

Supply in welding wire and spring wire in coil form and cut length.

Inconel 718 washer & gasket

Dimension can be customized with bright surface and precision tolerance.

Inconel 718 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Inconel 718 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Inconel 718 Spring

Spring with AMS5699 Standards according to clients drawing or specification

Inconel 718 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Alloy 718 Gas Tubing Hanger

Can be produced according to clients drawing or smaples with precision tolerance.

Inconel 718 Fasetners

Alloy 718 materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Why Inconel 718 ?

Inconel 718 is Austenitic structure, precipitation hardening generate “γ” made it excellent mechanical performance. G rain boundary generate “δ” made it the best plasticity in the heat treatment.with extremely resistance to stress corrosion cracking and pitting ability in high temperature or low temperature environments, especially the inoxidability in the high temperature.

1.workability

2.High tensile strength,endurance strength,creep strength and rupture strength at 700℃.

3.High inoxidability at1000℃.

4.Steady mechanical performance in the low temperature.

Inconel 718 Application field:

The elevated temperature strength, excellent corrosion resistance and workability at 700℃ properties made it use in a wide range of high requirement environments.Inconel grades are fit for use in the production of components that are employed in the severe environments such as turbocharger rotors & seals, motor shafts for electric submersible well pump, steam generators, tubes for heat exchangers, firearm sound suppressor blast baffles and in machine guns, black box recorders in aeroplanes etc.

• Steam turbine

• Liquid-fuel rocket

• Cryogenic engineering

• Acid environment

• Nuclear engineering

Our company Products Forms

Bars & Rods

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Seamless Tube & Welded Tube

Nickel/ Titanium Alloy tubes, U-bend /heat exchange tube

Bolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Sheet & Plates

Hastelloy/Inconel/ Incoloy/ Cobalt/Tianium

Strip & Foil

Hastelloy/Inconel/ invar/ soft magnetic Alloys ect

High Temperature Springs

Inconel 718/Inconel x750/ Nimonic 80A

Wire & Welding

Cobalt Alloy wire, Nickel alloy wire,Tianium Alloy wire

Special Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Oil Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Nickel Based Alloys

Welding Materials

Cobalt Based Alloys

Special Stainless Steels

Precision Alloys

Titanium Alloys

Want to Learn More or get a quote ?

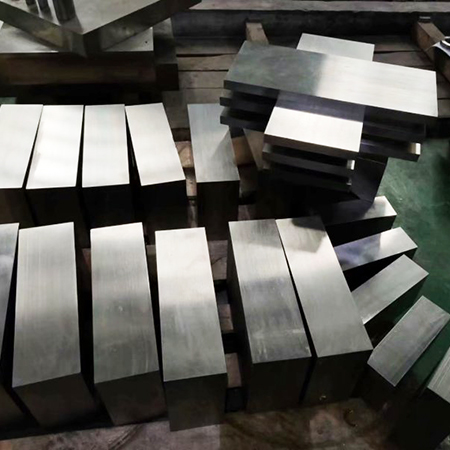

Product detail pictures:

Related Product Guide:

electropolished

Why Nickel Based Alloys ?

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for OEM/ODM China Nickel Alloy Flanges - Inconel 718 Tubing hanger – Sekonic , The product will supply to all over the world, such as: Azerbaijan, Bangladesh, Houston, To win customers' confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.