OEM/ODM China Stellite Alloy Sleeve – Titanium Disc – Sekonic

OEM/ODM China Stellite Alloy Sleeve – Titanium Disc – Sekonic Detail:

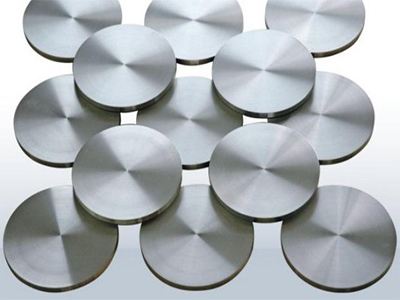

Titanium Disc is usually used to make be machined into titanium flange or Titanium tubesheet for heat exchanger equipment.

As a company with more than 20 years of production experience, we have a series of rigorous forging process and operation manual, including the heating steps, heating time and heat preservation time. The 35MN and 16MN rapid forging machine guaranteed the multiple forging in the suitable temperature range. And the forging technology could change the physical structure of titanium disc. Greatly improved the quality of titanium disc level.

• Tittanium Disc Materials: Pure Titanium,Grade1, Grade 2, Grade 5, Grade 5, Grade7 ,Grade9,Grade11, Grade12, Grade 16, Grade23 ect

• Forms: Standards Size or as per clients drawing.

• Dimension:OD: 150~1500mm, Thickness: 35~250mm,Customized

• Standards: ASTM B265, ASTM B381

• Inspection:Chemical composition test→Physical properties test→Macroscopic examinatio→Ultrasonic flaw detection→Appearance defects inspection

| Titanium Alloys Material Common Name | ||

|

Gr1 |

UNS R50250 |

CP-Ti |

|

Gr2 |

UNS R50400 |

CP-Ti |

|

Gr4 |

UNS R50700 |

CP-Ti |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

|

G9 |

UNS R56320 |

Ti-3AL-2.5V |

|

G11 |

UNS R52250 |

Ti-0.15Pd |

|

G12 |

UNS R53400 | Ti-0.3Mo-0.8Ni |

|

G16 |

UNS R52402 | Ti-0.05Pd |

|

G23 |

UNS R56407 |

Ti-6Al-4V ELI |

♦ Titanium Disc Chemical composition ♦

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C (≤) |

O (≤) |

N (≤) |

H (≤) |

Fe (≤) |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5 6.75 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12 0.25 |

— |

0.12 0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5 3.5 |

2.0 3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12 0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6 0.9 |

0.2 0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04 0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5 6.5 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

♦ Titanum Disc Physical Properties ♦

|

Grade |

Physical properties |

|||||

|

Tensile strength Min |

Yield strength Min (0.2%,offset) |

Elongation in 4D Min (%) |

Reduction of Area Min (%) |

|||

|

ksi |

MPa |

ksi |

MPa |

|||

|

Gr1 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

Gr5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

Gr7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

Gr11 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr12 |

70 |

483 |

50 |

345 |

18 |

25 |

|

Gr16 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr23 |

120 |

828 |

110 |

759 |

10 |

15 |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

• Grade 1: Pure Titanium, relatively low strength and high ductility.

• Grade 2: The pure titanium most used. The best combination of strength

• Grade 3: High strength Titanium, used for Matrix-plates in shell and tube heat exchangers

• Grade 5: The most manufactured titanium alloy. Exceedingly high strength. high heat resistance.

• Grade 7: Superior corrosion resistance in reducing and oxidizing environments.

• Grade 9: Very high strength and corrosion resistance.

• Grade 12: Better heat resistance than pure Titanium. Applications as for Grade 7 and Grade 11.

• Grade 23: Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for surgical implant application.

Product detail pictures:

Related Product Guide:

Why Cobalt based Alloys

electropolished

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for OEM/ODM China Stellite Alloy Sleeve – Titanium Disc – Sekonic , The product will supply to all over the world, such as: Croatia, Slovakia, Angola, If you need any of our products, or have other items to be produced, please send us your inquiries, samples or detailed drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.