Top Suppliers Alloy 400 Bar - Haynes 25 Udimet Alloy L-605 bar Wire/Ring – Sekonic

Top Suppliers Alloy 400 Bar - Haynes 25 Udimet Alloy L-605 bar Wire/Ring – Sekonic Detail:

Common Trade Names: Haynes 25, Alloy L605, Cobalt L605,GH5605, Udimet L605, UNS R30605

Haynes 25(AlloyL605) is a solid solution strengthened cobalt-chromium-tungsten nickel alloy with excellent high -temperature strength and excellent oxidation resistance to 2000°F(1093°C). The alloy also offers good resistance to sulfidation and resistance to wear and galling. Alloy L-605 is useful in gas turbine applications such as rings,blades and combustion chamber parts (sheet fabrications) and can also can be used in industrial furnace applications such as muffles or liners in high temperature kilns.

Haynes 25(Alloy L605) Chemical Composition

| C | Cr | Ni | Fe | W | Co | Mn | Si | S | P |

| 0.05-0.15 | 19.0-21.0 | 9.0-11.0 | ≦3.0 | 14.0-16.0 | balance | 1.0-2.0 | ≦0.4 | ≦0.03 | ≦0.04 |

Haynes 25(Alloy L605) Physical Properties

| Density (g/cm3) |

Melting point (℃) |

Specific heat capacity (J/kg·℃) |

Electric resistivity (Ω·cm) |

Thermal conductivity (W/m·℃) |

| 9.27 | 1300-1410 | 385 | 88.6×10E-6 | 9.4 |

Haynes 25(Alloy L605) Mechanical Properties

Representative Tensile Properties, Sheet

| Temperature, °F | 70 | 1200 | 1400 | 1600 | 1800 |

| Ultimate Tensile Strength, ksi | 146 | 108 | 93 | 60 | 34 |

| 0.2% Yield Strength, ksi | 69 | 48 | 41 | 36 | 18 |

| Elongation, % | 51 | 60 | 42 | 45 | 32 |

Typical Stress-Rupture Strength

| Temperature, °F | 1200 | 1400 | 1500 | 1600 | 1700 | 1800 |

| 100 Hours, ksi | 69 | 36 | 25 | 18 | 12 | 7 |

| 1,000 Hours, ksi | 57 | 26 | 18 | 12 | 7 | 4 |

Haynes 25(Alloy L605) Standards and Specifications

AMS 5537, AMS 5796,EN 2.4964,GE B50A460,UNS R30605,Werkstoff 2.4964

| Bar/Rod | Wire/Welding | Strip/Coil | Sheet/Plate | Pipe/Tube |

| AMS 5537 |

AMS 5796/5797 |

AMS 5537 | AMS 5537 | – |

Haynes 25(Alloy L605) Available Products in Sekonic Metals

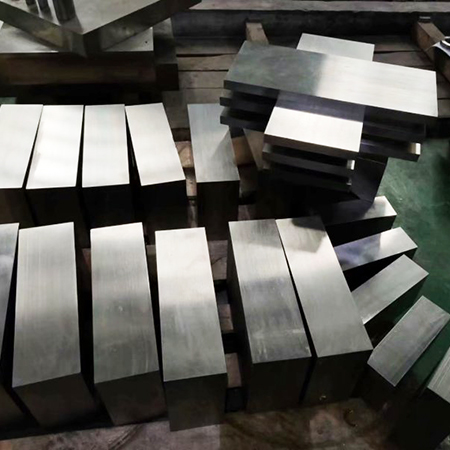

Alloy L605 Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Alloy L605 welding wire

Supply in welding wire and spring wire in coil form and cut length.

Alloy L605 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Alloy L605 Gasket/ Ring

Dimension can be customized with bright surface and precision tolerance.

Alloy L605 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Why Inconel Haynes 25(Alloy L605) ?

• Outstanding high temperature strength

• Oxidation resistant to 1800°F

• Galling resistant

• Resistant to marine environments, acids and body fluids

Haynes 25(Alloy L605) Application field:

• Gas turbine engine components such as combustion chambers and afterburners

• High temperature ball bearings and bearing races

• Springs

• Heart valves

Product detail pictures:

Related Product Guide:

electropolished

Why Nickel Based Alloys ?

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for Top Suppliers Alloy 400 Bar - Haynes 25 Udimet Alloy L-605 bar Wire/Ring – Sekonic , The product will supply to all over the world, such as: Gambia, Washington, Macedonia, If you have any requests, pls email Us with your detailed demands, we will give you the most wholesale Competitive Price with the Super Quality and the Unbeatable First-class Service ! We can give you the most competitive prices and high quality, because we are much more PROFESSIONAL! So please do not hesitate to contact us.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.