2021 China New Design Nickel Alloy Tube - Inconel 600 BAR /sheet /Seamless tube /Strip/ Bolts – Sekonic

2021 China New Design Nickel Alloy Tube - Inconel 600 BAR /sheet /Seamless tube /Strip/ Bolts – Sekonic Detail:

Common Trade Names: Alloy 600,UNS N06600,W.Nr. 2.4816

Inconel 600 Tube, Alloy 600 Tubing, ASTM B163 B167 ASME SB163 SB167 N06600 Inconel 600 DIN 17751 2.4816 is a nickel-chromium alloy used for applications that require corrosion and high temperature resistance. This nickel alloy was designed for service temperatures from cryogenic to elevated temperatures in the range of 1090 C (2000 F). It is non-magnetic, has excellent mechanical properties, and presents the desirable combination of high strength and good weldability under a wide range of temperatures. The high nickel content in UNS N06600 enables it to retain considerable resistance under reducing conditions, makes it resistant to corrosion by a number of organic and inorganic compounds, gives it excellent resistance to chloride-ion stress-corrosion cracking and also provides excellent resistance to alkaline solutions. Typical applications of this nickel alloy include the chemical, pulp and paper, aerospace, nuclear engineering and heat treating industries.

Inconel 600 Chemical Composition

| Alloy |

% |

Cr |

Fe |

Ni+Co |

C |

Mn |

Si |

S |

Cu |

Ti |

|

600 |

Min. |

14.0 | 6.0 | - | - | - | - | - | - |

0.7 |

|

Max. |

17.0 |

10.0 |

72.0 | 0.15 | 1.0 | 0.5 | 0.015 | 0.5 |

1.15 |

Inconel 600 Physical Properties

| Density | 8.47 g/cm³ |

| Melting point | 1354-1413 ℃ |

Inconel 600 Mechanical properties in the room temperature

| Status |

Tensile strength ksi MPa |

Yield strength Rp 0. 2 ksi MPa |

Elongation As % |

Brinell hardness HB |

| Annealing treatment | 80(550) | 35(240) | 30 | ≤195 |

Inconel 600 Standards and Specifications

| Bar/Rod | Wire | Strip/Coil | Sheet/Plate | Pipe/Tube | Other |

| ASTM B 166/ASME SB 166, ASTM B 564/ASME SB 564, ASME Code Cases 1827 and N-253SAE/AMS 5665, 5687BS 3075NA14, 3076NA14, DIN 17752, 17753 and 17754ISO 97239724, and 9725MIL-DTL-23229QQ-W-390 | ASTM B 166/ASME SB 166, ASTM B 564/ASME SB 564, ASME Code Cases 1827 and N-253, SAE/AMS 5665 and 5687BS 3075NA14, 3076NA14, DIN 17752, 17753, 17754, ISO 97239724, 9725, MIL-DTL-23229QQ-W-390 | ASTM B 168/ASME SB 168, ASTM B 906/ASME SB 906, ASME Code Cases 1827 and N-253, SAE/AMS 5540, BS 3072NA14 and 3073NA14, DIN 17750ISO 6208EN 10095, MIL-DTL-23228 | ASTM B 168/ASME SB 168, ASTM B 906/ASME SB 906, ASME Code Cases 1827 and N-253SAE/AMS 5540BS 3072NA14, 3073NA14, DIN 17750, ISO 6208, EN 10095, MIL-DTL-23228 | ASTM B 167/ASME SB 167, ASTM B 163/ASME SB 163, ASTM B 516/ASME SB 516, ASTM B 517/ASME SB 517, ASTM B 751/ASME SB 751, ASTM B 775/ASME SB 775, ASTM B 829/ASME SB 829, ASME Code Cases 1827N-20, N-253, and N-576SAE/AMS 5580, DIN 17751, ISO 6207, MIL-DTL-23227 | ASTM B 366/ASME SB 366, DIN 17742, ISO 4955A, AFNOR NC15Fe |

Inconel 600 Available Products in Sekonic Metals

Inconel 600 bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Inconel 600 welding wire

Supply in welding wire and spring wire in coil form and cut length.

Inconel 600 Forging Ring

Forging Ring or gasket,size can be customized with bright surface and precision tolerance

Inconel 600 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

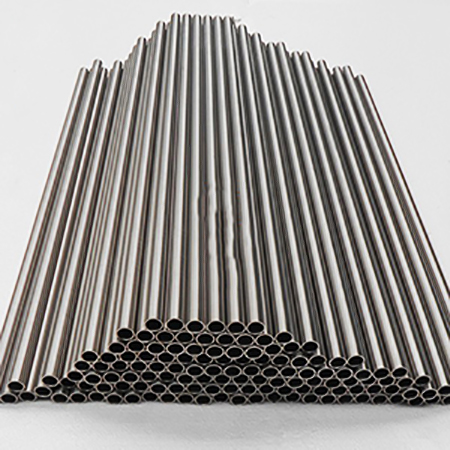

Inconel 600 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Inconel 600 Flange

Standards size and customized drawing can be produced by us with precsion tolerance

Inconel 600 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Inconel 600 Fasteners

Alloy 600 materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Why Inconel 600 ?

Ni-Cr-lron alloy.solid solution strengthening.

Good resistance to high temperature corrosion and oxidation resistance.

Excellent hot and cold processing and welding performance

A satisfactory heat intensity and high plasticity until 700℃.

Can be strenathened through the cold work.also can use resistance welding,welding or soldering connection.

Good corrosion resistance:

Corrosion resistance to all kinds of corrosive media

Chromium compounds make the alloy have better corrosion resistance than nickel 99.2 (200) alloy and nickel (alloy 201.low carbon) under the condition of oxidation

At the same time the high content of nickel alloy shows good corrosion resistance in alkaline solution and in reduction conditions.and.can effectively prevent the chloride-iron stress corrosion cracking

Very good corrosion resistance in acetic acid.acetic acid. formic acid.stearic acid and other organic acids.and corrosion resistance in.inorganic acid media.

Excellent corrosion resistance in a nuclear reactor in primarv and secondarv circulation use of high purity water

Particular prominent performance is the ability to resist dry chlorine and hydrogen chloride corrosion. application temperature can be up to 650 ℃.At high temperature, the alloy of annealing and solid solution treatment states in air has the very good antioxidant performance and high peeling strength

The alloy also shows resistance to ammonia and nitriding and carburizing atmosphere. but in the REDOX conditions changed alternately, alloy will be influenced by partial oxidation corrosion media.

Inconel 600 Application field:

Application field is very broad: aircraft engine parts,erosion thermowells in atmosphere,the production and use of caustic alkali metal field,especially the use of sulfur in the environment,the heat treatmen furnace retort and components,especially in the carbide and nitride atmosphere,petrochemical industry in the production of catalytic regenerator and reactor,etc.

Product detail pictures:

Related Product Guide:

Why Nickel Based Alloys ?

Special Materials we offer

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for 2021 China New Design Nickel Alloy Tube - Inconel 600 BAR /sheet /Seamless tube /Strip/ Bolts – Sekonic , The product will supply to all over the world, such as: Mauritius, Brasilia, Cancun, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we've insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.