AMS ASME ASTM for inconel625 alloy navigators

AMS ASME ASTM for inconel625 alloy navigators,

625 Alloy,Inconel 625 Bars ,Inconel 625 Rods,Inconel 625 sheet ,Inconel 625 plate,Inconel 625 strip,Inconel 625 coil,

Common Trade Names: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr. 2.4856

Inconel Alloy 625 is a non-magnetic, corrosion and oxidation resistant, nickel-chromium alloy. The high strength of Inconel 625 is the result of the stiffening combination of molybdenum and niobium on the nickel chromium base of the alloy. Inconel 625 has tremendous resistance to a wide range of unusually severe corrosive environments including high-temperature effects such as oxidation and carburization. Its outstanding strength and toughness in temperature ranges from cryogenic temperatures to high temperature up to 2000° F (1093° C) are derived primarily from the solid solution effects of the refractory metals Columbium and molybdenum in a nickel-chromium matrix.

Inconel 625 Chemical Composition

|

% |

Ni |

Cr |

Fe |

Mo |

Nb+Ta |

Co |

C |

Mn |

Si |

S |

Al |

Ti |

P |

|

Min. |

58.0 |

20.0 |

- |

8.0 |

3.15 |

- | - | - | - | - |

- |

- | - |

|

Max. |

- |

23.0 |

5.0 |

10.0 |

4.15 |

1.0 |

0.1 |

0.5 |

0.5 |

0.015 |

0.4 |

0.4 |

0.015 |

Inconel 625 Physical Properties

| Density | 8.4 g/cm³ |

| Melting point |

1290-1350 ℃

|

Inconel 625 Typical Mechanical Properties

| Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution treatment | 827 | 414 | 30 | ≤220 |

Inconel 625 Standards and Specifications

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE MR0175-3,

UNS N06625, Werkstoff 2.4856

| Wire | Sheet | Strip | Rod | Pipe | |

| AMS 5599, AMS 5666,AMS 5837, AMS 5979,ASTM B443 | ASTM B443 | AMS 5599, AMS 5979,ASTM B443 | ASTM B 446 SAE/AMS 5666,

VdTÜV 499 |

Seamless Pipe | Welded Pipe |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

Inconel 625 Available Products in Sekonic Metals

Inconel 625 Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Inconel 625 welding wire

Supply in welding wire and spring wire in coil form and cut length.

Inconel 625 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

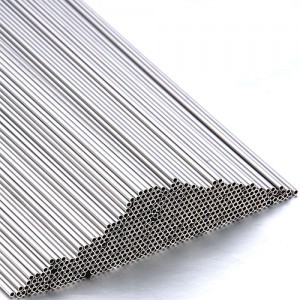

Inconel 625 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Inconel 625 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Inconel 625 Fasteners

Alloy 625 we can offer bolts,Nuts and other fasteners as clients requirements

Inconel 625 Features :

1.High creep-rupture strength

2.Oxidation resistant to 1800°F

3.Good fatigue resistance

4.Excellent weldability

5.Outstanding resistance to chloride pitting and crevice corrosion

6.Immune to chloride ion stress corrosion cracking

7.Resistant to seawater under both flowing and stagnant conditions and under fouling

Inconel 625 Application field:

• Aircraft ducting systems

• Jet engine exhaust systems

• Engine thrust-reverser systems

• Bellows and expansion joints

• Turbine shroud rings

• Flare stacks

• Seawater components

• Chemical process equipment handling mixed acids both oxidizing and reducing.

Our company Products Forms

Bars & Rods

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Seamless Tube & Welded Tube

Nickel/ Titanium Alloy tubes, U-bend /heat exchange tube

Bolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Sheet & Plates

Hastelloy/Inconel/ Incoloy/ Cobalt/Tianium

Strip & Foil

Hastelloy/Inconel/ invar/ soft magnetic Alloys ect

High Temperature Springs

Inconel 718/Inconel x750/ Nimonic 80A

Wire & Welding

Cobalt Alloy wire, Nickel alloy wire,Tianium Alloy wire

Special Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Oil Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Nickel Based Alloys

Welding Materials

Cobalt Based Alloys

Special Stainless Steels

Precision Alloys

Titanium Alloys

Want to Learn More or get a quote ?

Get in Touch

What material is 625 alloy made of? A nickel – based alloy with high Ni – Cr – Mo.

Chemical composition of Alloy 625: Chromium (Cr)20.0-23.0, Iron (Fe)< 5.0, (Al) & lt; 0.4, Silicon (Si)< 0.50 manganese (Mn)< 0.50, Nickel (Ni)258, sulfur (S)< 0.015, Cobalt (Co)< 1.0,(Mo)8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P)< 0.015,(Nb) 3.15-4.15, Carbon (C)< 0.01.

625 Alloy features excellent oxidation and corrosion resistance, excellent strength and toughness, excellent fatigue resistance, high formability, and excellent weldability. It can maintain its strength and toughness anywhere from low temperatures to 2000°F. Due to the rapid hardening of alloy 625, a large amount of cold forming may require annealing throughout the cold forming process. The alloy is commonly used in jet engines and other aerospace applications.