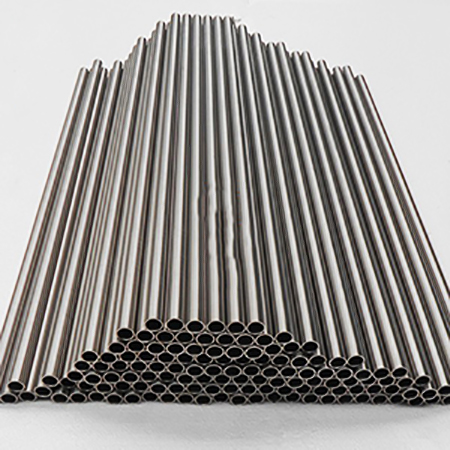

Chinese wholesale Alloy 904l Flange - Titanium Pipe and Tube – Sekonic

Chinese wholesale Alloy 904l Flange - Titanium Pipe and Tube – Sekonic Detail:

• Tittanium Pipe and Tube Materials: Pure Titanium(CP) and Titanium alloy foil,Grade1, Grade 2, Grade 5, Grade 5, Grade 7 and Grade 9

• Types: Seamless Tube, Welded Tube, Coil Tube, Heat exchanger tube, U-Bend Tube, Capillary Tube

• Dimension: OD: 3~1500mm, WT: 0.2~25mm: Length: ≤19000mm

• Conditions: Rolling, Welding, Machining

• Standards: ASTM B338, ASTM B337, ASTM B861, ASTM B862 etc

• Appilications:Shell and tube heat exchanger, condenser, evaporator, pipeline, Seawater desalination equipment,Bike rack,Marine pressure tube,Oil drilling pressure tube,

| Titanium Alloys Material Common Name | ||

|

Gr1 |

UNS R50250 |

CP-Ti |

|

Gr2 |

UNS R50400 |

CP-Ti |

|

Gr4 |

UNS R50700 |

CP-Ti |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

|

G9 |

UNS R56320 |

Ti-3AL-2.5V |

|

G11 |

UNS R52250 |

Ti-0.15Pd |

|

G12 |

UNS R53400 | Ti-0.3Mo-0.8Ni |

|

G16 |

UNS R52402 | Ti-0.05Pd |

|

G23 |

UNS R56407 |

Ti-6Al-4V ELI |

Titanium Pipe and Tubes : Titanium seamless tube is processed by the breakdown of titanium ingot, extruding to titanium tube billet. Then produce titanium tubes to appropriate size with series of processes such as multiple rolling, annealing, pickling, and grinding technology.

Titanium welded tube is by selecting a suitable thickness of the high quality cold rolled titanium plate, after the process of flattening, cutting and washing, then rolled up titanium plate into tubular, welding by the whole automatic welding equipment. Our advanced welding equipment guaranteed the quality of welding. Ultimately help to produce the excellent quality titanium tube.

♦ Titanium Pipes Chemical composition ♦

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C (≤) |

O (≤) |

N (≤) |

H (≤) |

Fe (≤) |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5 6.75 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12 0.25 |

— |

0.12 0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5 3.5 |

2.0 3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12 0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6 0.9 |

0.2 0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04 0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5 6.5 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

♦ Titanum Alloy Pipe Physical properties ♦

|

Grade |

Physical properties |

|||||

|

Tensile strength Min |

Yield strength Min (0.2%,offset) |

Elongation in 4D Min (%) |

Reduction of Area Min (%) |

|||

|

ksi |

MPa |

ksi |

MPa |

|||

|

Gr1 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

Gr5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

Gr7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

Gr11 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr12 |

70 |

483 |

50 |

345 |

18 |

25 |

|

Gr16 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr23 |

120 |

828 |

110 |

759 |

10 |

15 |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

• Grade 1: Pure Titanium, relatively low strength and high ductility.

• Grade 2: The pure titanium most used. The best combination of strength

• Grade 3: High strength Titanium, used for Matrix-plates in shell and tube heat exchangers

• Grade 5: The most manufactured titanium alloy. Exceedingly high strength. high heat resistance.

• Grade 7: Superior corrosion resistance in reducing and oxidizing environments.

• Grade 9: Very high strength and corrosion resistance.

• Grade 12: Better heat resistance than pure Titanium. Applications as for Grade 7 and Grade 11.

• Grade 23: Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for surgical implant application.

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Nickel Based Alloys ?

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Chinese wholesale Alloy 904l Flange - Titanium Pipe and Tube – Sekonic , The product will supply to all over the world, such as: Rotterdam, Italy, Malaysia, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!