Discountable price Valve Seat - Stainless Steel Nitronic 60 bar/ Pipe/Ring /Sheet – Sekonic

Discountable price Valve Seat - Stainless Steel Nitronic 60 bar/ Pipe/Ring /Sheet – Sekonic Detail:

Common Trade Names: Nitronic 60, Alloy 218,UNS S21800

Nitronic 60 is known for its excellent galling resistance, even at elevated temperatures. The additions of 4% silicon and 8% manganese inhibit wear, galling, and fretting. It is commonly used for various fasteners and pins that require strength and resistance to galling. It maintains decent strength up to temperatures of 1800°F and has oxidation resistance similar to that of 309 stainless steel. The general corrosion resistance is between that of 304 and 316 stainless steel.

Nitronic 60 Chemical Composition

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

N |

P |

S |

|

Nitronic 60 |

Min. |

8 |

16 |

59 |

|

7 |

3.5 |

0.08 |

|

|

|

Max. |

9 |

18 |

66 |

0.1 |

9 |

4.5 |

0.18 |

0.04 |

0.03 |

Nitronic 60 Physical Properties

| Density | 8.0 g/cm³ |

| Melting point | 1375 ℃ |

Nitronic 60 Mechanical Properties

|

Alloy status |

Tensile strength Rm N/mm² |

Yield strength RP0.2 N/mm² |

Elongation A5 % |

Brinell hardness HB |

| Solution treatment |

600 |

320 |

35 |

≤100 |

Nitronic 60 Standards and Specifications

AMS 5848,ASME SA 193, ASTM A 193

Nitronic 60 Available Products in Sekonic Metals

Nitronic 60 Bars & Rods

Round bars/Flat bars/Hex bars,Size From 8.0mm-320mm, Used for bolts,fastners and other parts

Nitronic 60 Wire

Supply in welding wire and spring wire in coil form and cut length.

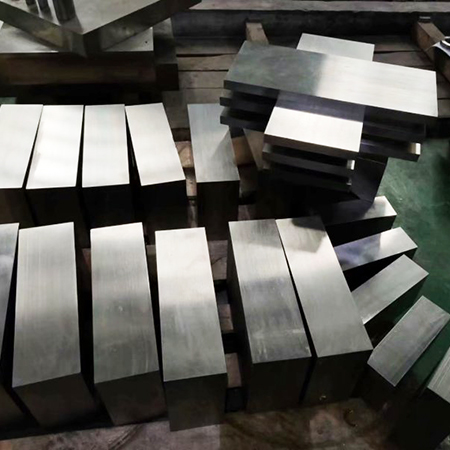

Nitronic 60 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Nitronic 60 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Nitronic 60 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Nitronic 60 Fasteners

Nitroinc 60 materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Why Nitronic 60 ?

• Nitronic 60 Stainless Steel provides a significantly lower cost way to fight galling and wear compared with cobalt-bearing and high nickel alloys. Its uniform corrosion resistance is better than type 304 in most media. In Nitronic 60 ,chloride pitting is superior to Type 316

• Yield strength at room temperature is nearly twice that of 304 and 316

• Nitronic 60 provides excellent high temperature oxidation resistance and low-temperature impact resistance

Nitronic 60 Application field:

Used extensively in the Power, Chemical, Petrochemical, Food and Oil & Gas industries with an array of uses including expansion joint wear plates, pump wear rings, bushings, process valve stems, seals and logging equipment.

Product detail pictures:

Related Product Guide:

electropolished

Special Materials we offer

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for Discountable price Valve Seat - Stainless Steel Nitronic 60 bar/ Pipe/Ring /Sheet – Sekonic , The product will supply to all over the world, such as: Ghana, Munich, Singapore, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!