Low price for Hastelloy X - Stainless Steel Alloy PH13-8Mo(13-8PH) – Sekonic

Low price for Hastelloy X - Stainless Steel Alloy PH13-8Mo(13-8PH) – Sekonic Detail:

Common Trade Names: 13-8Mo, PH13-8Mo, S51380, 04Cr13Ni8Mo2Al, xm-13,UNS S13800,Werkstoff 1.4548

PH13-8Mo stainless is a martensitic precipitation hardening stainless steel that has excellent strength, high hardness, superior toughness and good corrosion resistance. Good transverse toughness properties are achieved by tight chemical composition control, low carbon content, and vacuum melting. Typical applications are large airframe structural components and injection molding equipment.

PH13-8Mo Chemical Compositons

|

C |

Cr |

Ni |

Mo |

Si |

Mn |

P |

S |

Al |

N |

Fe |

|

≤ 0.05 |

12.25 13.25 |

7.5 8.5 |

2.0 2.5 |

≤ 0.1 |

≤ 0.2 |

≤ 0.01 |

≤ 0.008 |

0.9 1.35 |

≤ 0.01 |

Bal |

PH13-8Mo Physical Properties

|

Density |

Melting point |

|

7.76 |

1404-1471 |

PH13-8Mo Alloy Typical Mechanical Properties

Strength varies with heat treatment condition. The following table shows minimum mechanical properties for the various aged conditions, per AMS 5864

| H950 | H1000 | H1025 | H1050 | H1100 | H1150 | |

| 0.2 Offset Yield Strength, ksi | 205 | 190 | 175 | 165 | 135 | 90 |

| Ultimate Tensile Strength, ksi | 220 | 205 | 185 | 175 | 150 | 135 |

| Elongation in 2″, % | 10 | 10 | 11 | 12 | 14 | 14 |

| Reduction of Area, % (Longitudinal) | 45 | 50 | 50 | 50 | 50 | 50 |

| Reduction of Area, % (Transverse) | 45 | 50 | 50 | 50 | 50 | 50 |

| Reduction of Area, % (Short-Transverse) | 35 | 40 | 45 | 45 | 50 | 50 |

| Min Hardness, Rockwell | 45 | 43 | - | 40 | 34 | 30 |

PH 13-8Mo Standards and Specifications

AMS 5629,ASTM A 564,EN 1.4548,UNS S13800,Werkstoff 1.4548

PH 13-8Mo Available Products in Sekonic Metals

PH 13-8Mo Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

PH 13-8Mo sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

PH 13-8Mo strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Why PH13-8Mo ?

• High strength, good fracture toughness, transverse mechanical properties and stress corrosion resistance in Marine environment.

• Weldability:By an inert gas protection welding, also using most of the other welding process, including plasma welding, electron beam welding, And argon shielding gas is preferred.

PH13-8Mo Application field:

Widely used in aerospace, nuclear reactors and petrochemical and other fields, such as cold heading fasteners and

machining, aircraft components, reactor components and petrochemical equipment.

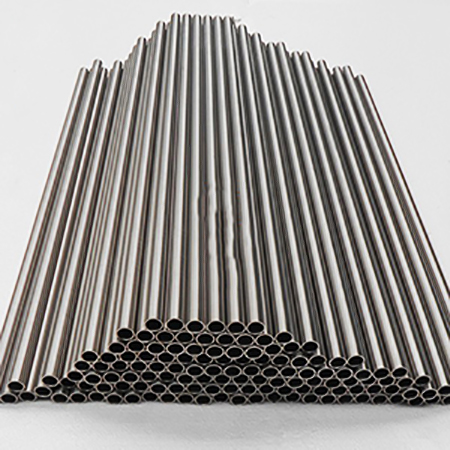

Product detail pictures:

Related Product Guide:

Why Cobalt based Alloys

Why Nickel Based Alloys ?

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for Low price for Hastelloy X - Stainless Steel Alloy PH13-8Mo(13-8PH) – Sekonic , The product will supply to all over the world, such as: Wellington, Libya, Sri Lanka, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products and ideas with us!!

A good manufacturers, we have cooperated twice, good quality and good service attitude.