OEM/ODM China Nickel Alloy Flanges - Hastelloy B/B2/B3 Round Bar – Sekonic

OEM/ODM China Nickel Alloy Flanges - Hastelloy B/B2/B3 Round Bar – Sekonic Detail:

Common Trade Names: Hastelloy B, NS3201,UNS N10001

Hastelloy B is a face-centered cubic lattice structure.

By controlling the content of Fe and Cr at a small value, the brittleness of processing is reduced and the precipitation of N4Mo phase between 700 ℃ and 870℃ is prevented.in the reduction of medium with very good corrosion resistance, such as a various temperature and concentration of hydrochloric acid. In the middle of the concentration of sulfuric acid solution (or contain a certain amount of chloride ions) also has very good corrosion resistance. At the same time can be used to acetic acid and phosphoric acid environment. Alloy material suitable only in the metallurgical structure and pure crystal structure in order to have the best corrosion resistance.

Hastelloy B Chemical Composition

| Alloy |

% |

Fe |

Cr |

Ni |

Mo |

V |

Co |

C |

Mn |

Si |

S |

P |

|

Hastelloy B |

Min. |

4.0 |

- |

balance |

26.0 | 0.2 | - | - | - | - | - |

- |

|

Max. |

6.0 |

1.0 |

30.0 |

0.4 | 2.5 | 0.05 | 1.0 | 1.0 | 0.03 | 0.04 |

Hastelloy B Physical Properties

| Density | 9.24 g/cm³ |

| Melting point | 1330-1380 ℃ |

Hastelloy B Mechanical Properties

| Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution treatment | 690 | 310 | 40 | - |

Hastelloy B Standards and Specifications

| Bar/Rod | Strip/Coil | Sheet/Plate | Pipe/Tube | Forging |

| ASTM B335,ASME SB335 | ASTM B333,ASME SB333 | ASTM B662,ASME SB662 ASTM B619,ASME SB619 ASTM B626 ,ASME SB626 |

ASTM B335,ASME SB335 | |

Hastelloy B Available Products in Sekonic Metals

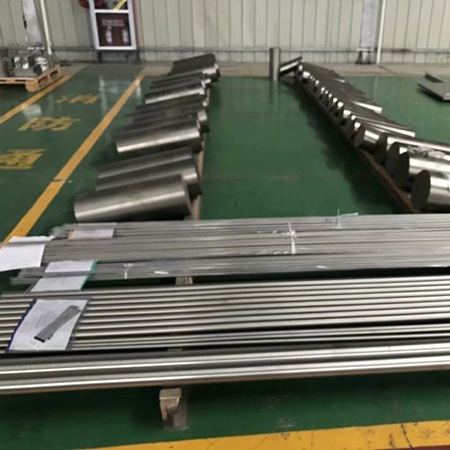

Hastelloy B Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Hastelloy B seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Hastelloy B sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Hastelloy B Fasteners

Hastelloy B materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Hastelloy B strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Why Hastelloy B ?

• Excellent corrosion resistance for reductive environment.

• Excellent resistance to sulfuric acid (except for concentrated) and other non-oxidizing acids.

• Good resistance to stress corrosion cracking (SCC) caused by chlorides.

• Excellent resistance to corrosion caused by organic acids.

• Good corrosion resistance even for welding heat affect zone due to low concentration of carbon and silicon.

Hastelloy B Application field:

Widely used in the chemical, petrochemical, energy manufacturing and pollution control related processing and

equipment,especially in the processes dealing with various acids (sulfuric acid, hydrochloric acid,

phosphoric acid, acetic acid and so on.

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Nickel Based Alloys ?

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for OEM/ODM China Nickel Alloy Flanges - Hastelloy B/B2/B3 Round Bar – Sekonic , The product will supply to all over the world, such as: Brunei, Bogota, Florida, Wide selection and fast delivery to suit your needs! Our philosophy: Good quality, great service, keep improving. We've been looking forward that more and more oversea friends join in our family for further development near the future!

We have been looking for a professional and responsible supplier, and now we find it.